10 Best Welding Wire 2026 in the United States

Our technology thoroughly searches through the online shopping world, reviewing hundreds of sites. We then process and analyze this information, updating in real-time to bring you the latest top-rated products. This way, you always get the best and most current options available.

Our Top Picks

Winner

ARCCAPTAIN Mig Welding Wire, 0.035 10Lb Mig Wire ER70S-6 10Lbs Gas Solid Carbon Steel Low Splatter Mig Welding Wire Compatible With Lincoln Miller Forney Harbor Welder 0.09 4.5KG

Most important from

661 reviews

The ARCCAPTAIN Mig Welding Wire is a solid choice for those needing a reliable 0.035-inch diameter carbon steel wire, especially if you're using compatible machines like Lincoln, Miller, Forney, or Harbor welders. Weighing 10 pounds, the spool size is convenient for both hobbyists and more frequent welders, making it manageable without frequent changes.

This wire is designed for MIG welding with shielding gas, featuring a balanced mix of manganese and silicon that helps remove impurities during welding, resulting in cleaner and stronger welds. Users appreciate its smooth feeding and consistent arc, which minimizes spatter and makes the welding process easier and neater. The wire’s performance delivers good penetration and a nice-looking weld bead, reducing the need for extra cleaning afterwards. TÜV certification adds confidence in its quality and reliability.

It works well for most common MIG welding tasks, but as a solid wire, it requires a shielding gas, so it’s not ideal if you want a flux-core option that can weld without gas. This wire is suitable for both beginners and experienced welders looking for stable, high-quality carbon steel wire for general welding purposes.

Most important from

661 reviews

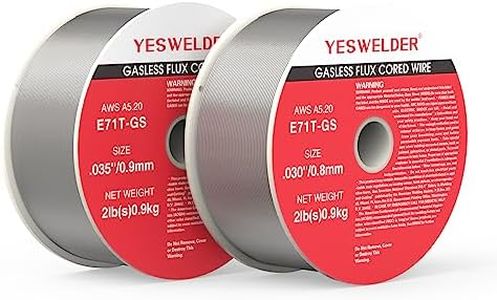

ARCCAPTAIN Flux Core Welding Wire .035, E71T-GS 035" Flux Core Welding Wire Gasless Low Splatter 10Lbs Mig Welding Wire Mild Carbon Steel Compatible With Lincoln Miller Forney Harbor Welder 4.5KG

Most important from

2470 reviews

The ARCCAPTAIN Flux Core Welding Wire .035 is a solid choice if you're looking for an easy-to-use welding wire that doesn’t require shielding gas. It comes in a 10-pound spool with a 0.035-inch diameter, which is a common and versatile size suitable for many welding tasks like T-joints, butt welds, and lap welds. Being AWS E71T-GS certified means it’s designed for gasless flux core welding, making it great for outdoor or windy conditions where using shielding gas can be tricky.

This wire is made for mild carbon steel and offers good strength and corrosion resistance, so your welds should be durable and reliable. The vacuum-sealed packaging is a nice touch to keep the wire clean and ready to use, helping maintain quality over time. It’s compatible with popular welders like Lincoln, Miller, and Forney, which covers many common brands. While flux core wires offer convenience and portability, their weld finish might have more spatter compared to gas-shielded wires, so some cleanup can be expected. It’s mainly suited for mild steel, so it won’t be the best option if you need to weld other metals.

This wire is particularly well-suited for general shop work, repairs, and projects where ease of use and flexibility matter more than the absolute cleanest weld appearance.

Most important from

2470 reviews

PGN Solid MIG Welding Wire - ER70S-6 .023 Inch - 10 Pound Spool - Mild Steel MIG Wire with Low Splatter and High Levels of Deoxidizers - for All Position Gas Welding

Most important from

2120 reviews

The PGN Solid MIG Welding Wire ER70S-6 with a 0.023-inch diameter is designed for mild steel welding and works well with gas-shielded MIG welding processes. Its key strength lies in low spatter production, which helps create clean, professional-looking welds whether you're doing simple or complex joints like T-joints, butt welds, or lap welds. The wire’s high levels of silicon and manganese deoxidizers improve weld quality by reducing impurities, making it a good choice for users who want smooth, reliable beads.

The 10-pound spool size offers good value for money and is packaged carefully to avoid tangles, which is helpful whether you’re a professional welder or a hobbyist working on various projects. The wire’s copper finish and solid core make it dependable for all-position welding, adding to its versatility. On the downside, the product is unfinished, so some users might need to ensure proper surface preparation depending on their specific welding environment. Also, while the 0.023-inch diameter is versatile, it might not be suitable for very heavy-duty or thick metal work that requires thicker wire. The product does require a suitable shielding gas, so you’ll need the right gas setup for best results.

This MIG welding wire serves as a reliable option for mild steel welding, offering good control and minimal cleanup due to reduced spatter. The spool size supports medium-scale projects effectively without being cost-prohibitive.